Heat/Surface Treatment Technology

Our heat treatment is to offer consistent quality as well as fully demonstrating products’ performance using the characteristics of the materials all the time. Optimum heat treatment is processed for different object like brilliantquenching using vacuum furnace or die-quenching with high precision and high quality combination of high frequency induction hardening and pressprocessing. As surface treatment technique, CVD (ChemicalVapor Deposition) with in-house facility is offered.

Vacuum Heat Treatment

Vacuum heat treatment is a heat treatment method that heats and cools the product after making the inside of the kiln where the product is placed in a vacuum state. In the heat treatment in the atmosphere, due to the reaction between oxygen and iron, the steel surface has reduced hardness due to oxidation scale and decarburization, but in the vacuum heat treatment the steel surface becomes brilliant finish and nonuniform hardness is obtained I will. Our company conducts heat treatment which can fully demonstrate product functions by advanced heat treatment technology cultivated over many years.

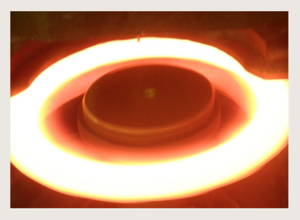

High Frequency Quenching

Vacuum heat treatment is a heat treatment method that heats and cools the product after making the inside of the kiln where the product is placed in a vacuum state. In the heat treatment in the atmosphere, due to the reaction between oxygen and iron, the steel surface has reduced hardness due to oxidation scale and decarburization, but in the vacuum heat treatment the steel surface becomes brilliant finish and nonuniform hardness is obtained I will. Our company conducts heat treatment which can fully demonstrate product functions by advanced heat treatment technology cultivated over many years.

Chemical Vapor Deposition (CVD) Coating

Surface treatment is a technique for forming a very hard ceramic film with a thickness of 3 to 5 μm on the surface of products. This coating increases the lubricity, abrasion resistance and corrosion resistance of the surface of the product and dramatically improves the product life. As a surface treatment method, our company have adopted a CVD method with excellent film adhesion, and we are supplying strong and stable hard films.

- Technical information

- Heat/Surface

Treatment - Plastic Forming

- Grinding/Polishing

- News

- News

- Company Profile

- Message

- Profile

- Philosophy/CSR

- Network

- History

- Product Info

- Screw Tool

- Auto Parts

- Industrial Precision Parts

- Technical Info

- Heat/Surface Treatment

- Plastic Forming

- Grinding/Polishing

- Evaluation & Development

- Measuring

- Evaluation

- Analysis

- Quality / Environment

- Quality/Environment Policy

- Recruit

- New Graduate

- Mid Career

- Entry Form

- Contact Us

- Contact Us

- Privacy Policy

2-1-49,Numame, Isehara-shi, Kanagawa, 259-1126, Japan

TEL:+81-463-94-5235 FAX:+81-463-93-5104